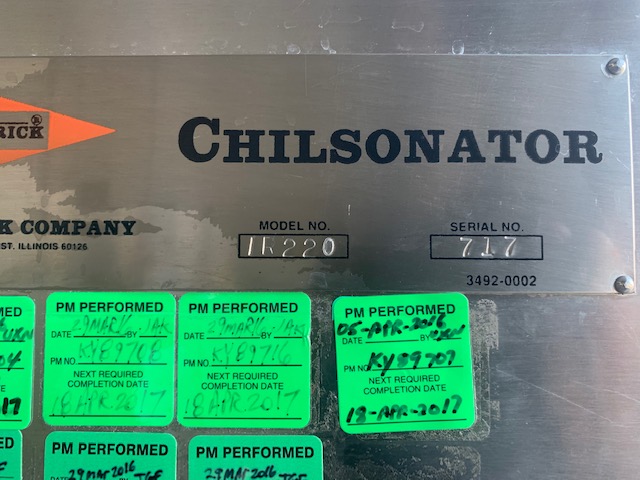

FITZPATRICK IR220 Mobile Roller Compactor Chilsonator - Stainless Steel Construction SOLD

| ProductName | : | FITZPATRICK IR220 Mobile Roller Compactor Chilsonator - Stainless Steel Construction SOLD |

| Item Number | : | P2009PIR1482 |

| Model | : | IR220 |

| Serial Number | : | 717 |

| Year | : |

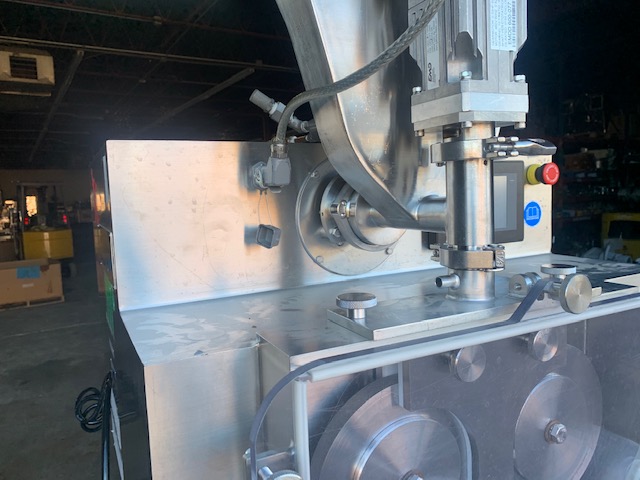

| Description | : | Fitzpatrick IR220 Mobile Roller Compactor Chilsonator Stainless steel construction Includes 3 sets of rolls : IR 220 / SN: 717 .Roll Compactor is ideal for lab, pilot plant and small production. Maximum process flexibility is acheived with: variable speed rolls and feed screws, variable roll pressure, roll gap measurement, and multiple roll configurations available. Benefits you can obtain from the IR 220 Chilsonator roll compactor are. Results can be applied to larger production scale units. Process batches as small as 50 grams and as large as 20 kg/hr with minimal loss. Easy to disassemble and clean. Multiple roll configurations available. Automated "operator friendly" PLC controls.otally enclosed process area All stainless steel construction. 8" diameter x .75" roll face width. Horizontal feed screw with hopper driven Vertical feed. On stainless steel base. Allen Bradley PLC controller and motor VFD controllers 230 volt. |

FITZPATRICK IR220 Mobile Roller Compactor Chilsonator - Stainless Steel Construction SOLD

| ProductName | : | FITZPATRICK IR220 Mobile Roller Compactor Chilsonator - Stainless Steel Construction SOLD |

| Item Number | : | P2009PIR1482 |

| Model | : | IR220 |

| Serial Number | : | 717 |

| Year | : |

| Description | : | Fitzpatrick IR220 Mobile Roller Compactor Chilsonator Stainless steel construction Includes 3 sets of rolls : IR 220 / SN: 717 .Roll Compactor is ideal for lab, pilot plant and small production. Maximum process flexibility is acheived with: variable speed rolls and feed screws, variable roll pressure, roll gap measurement, and multiple roll configurations available. Benefits you can obtain from the IR 220 Chilsonator roll compactor are. Results can be applied to larger production scale units. Process batches as small as 50 grams and as large as 20 kg/hr with minimal loss. Easy to disassemble and clean. Multiple roll configurations available. Automated "operator friendly" PLC controls.otally enclosed process area All stainless steel construction. 8" diameter x .75" roll face width. Horizontal feed screw with hopper driven Vertical feed. On stainless steel base. Allen Bradley PLC controller and motor VFD controllers 230 volt. |